ABOUT DAILOR

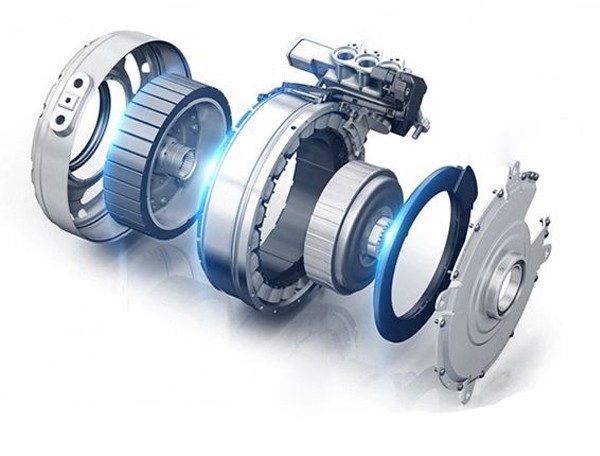

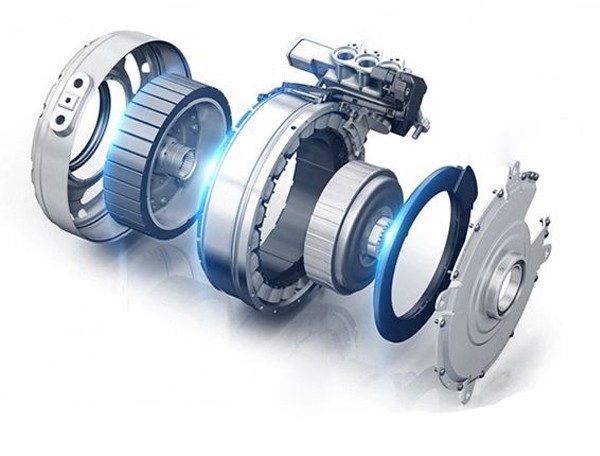

Pengfei Electronics has been a rich experience manufacturer in high-level custom AC motor since 2004, We have more than 15 years of experience in development and management of AC motors, and familiar with any problems in different situations of AC motors.

With many advanced production equipments, we guarantee the quality and delivery time in the development and production of motors, design the most optimized products according to the cost and quality requirements provided by .........

ABOUT ADVANTAGE

For more than a decade, the company has devoted itself to

building a supermarket dedicated to the supply of

electrical accessories.

PROFESSIONAL

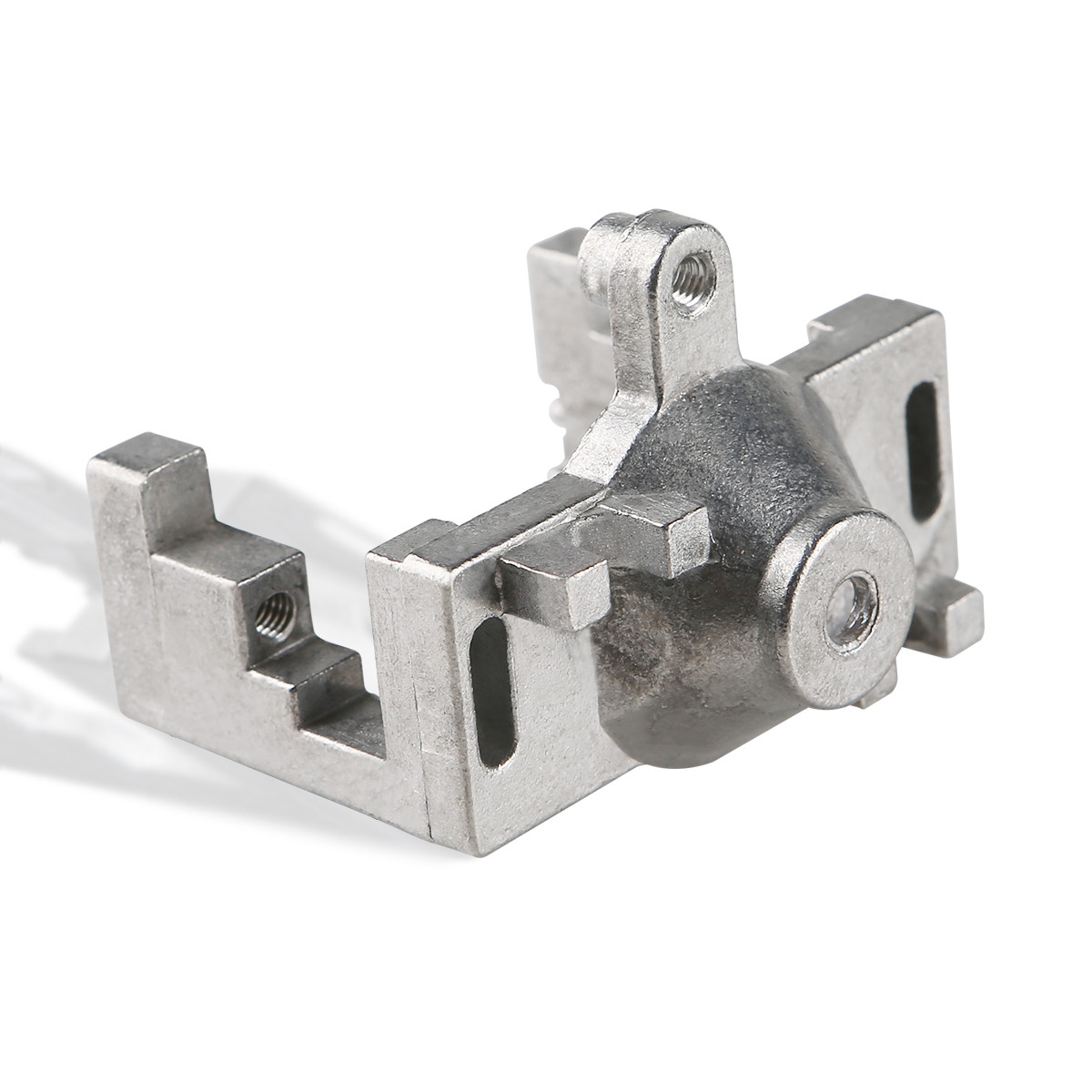

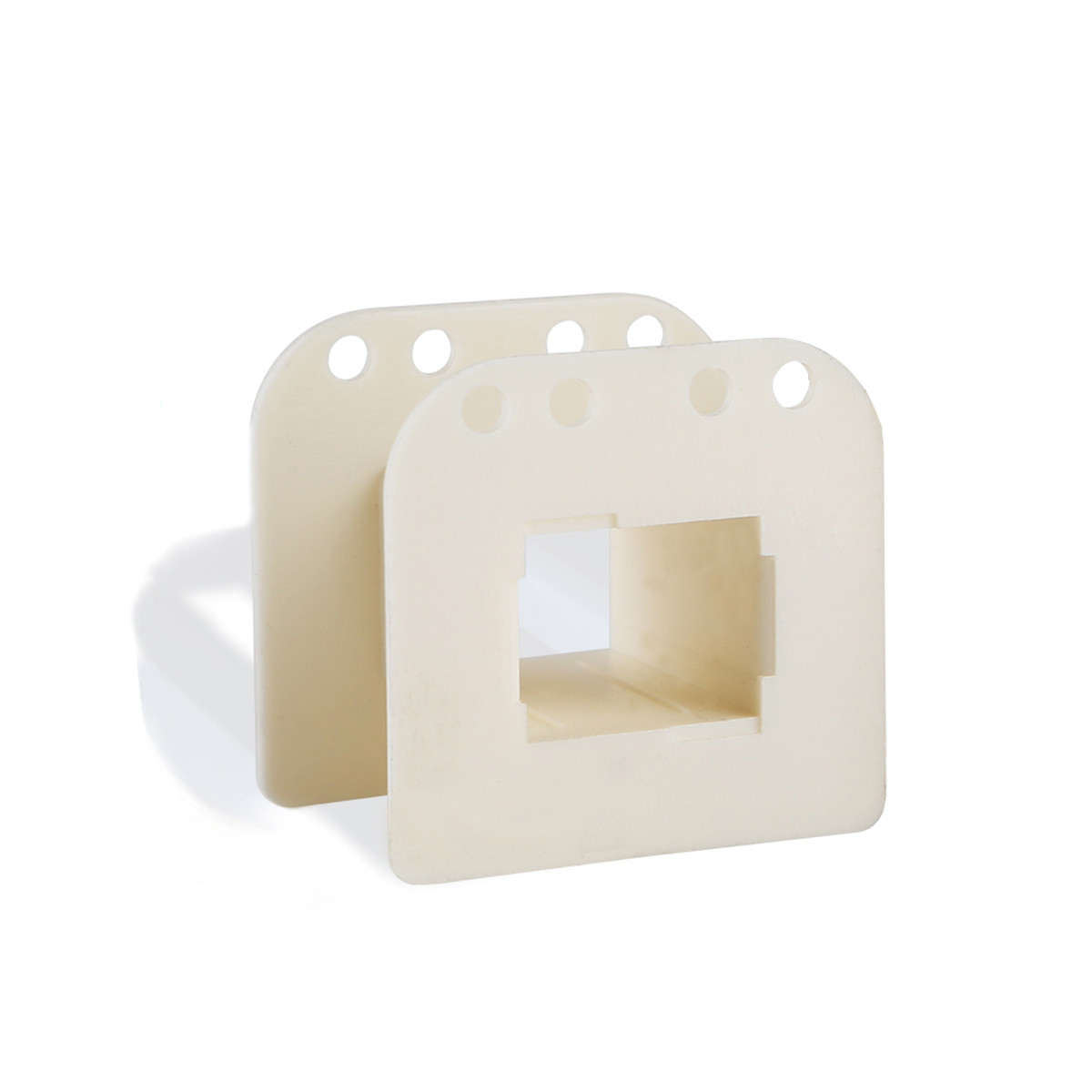

PRODUCTION

Focus on development,production and sales of customized AC motors.

FACTORY

OUTLETS

Strong technical force,complete production equipment.

SUPPORT

CUSTOMIZATION

There are ready-made samples,and we also accept sample processing

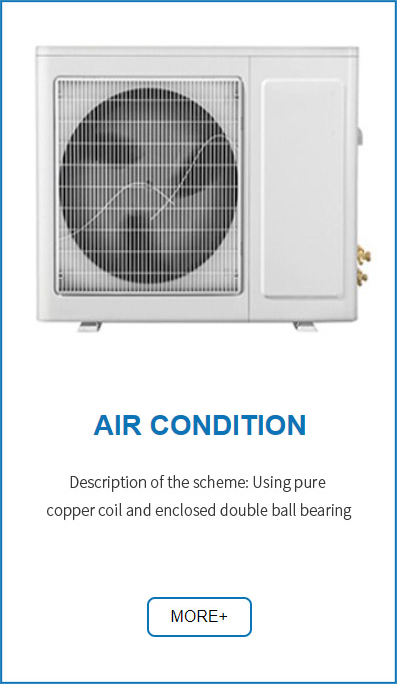

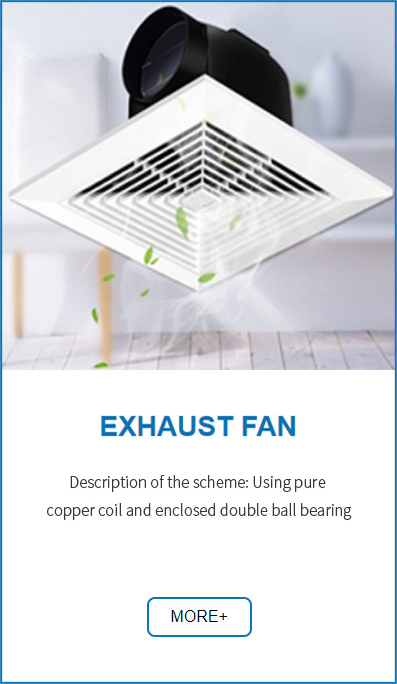

OUR PRODUCT

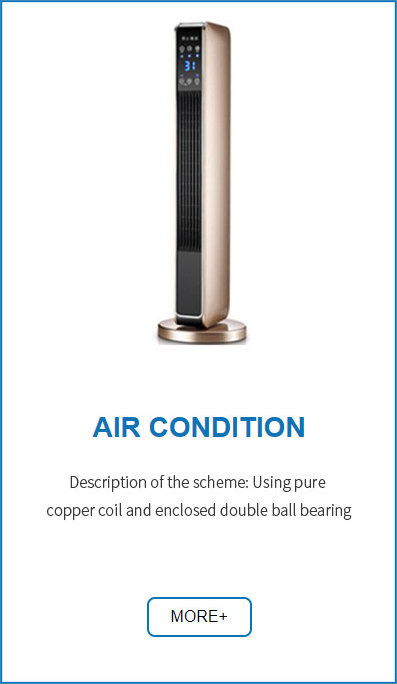

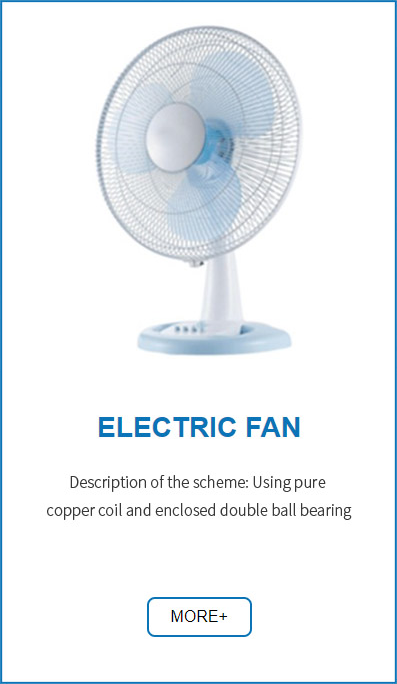

SOLUTION

For more than a decade, the company has devoted itself to building a supermarket dedicated to the supply of electrical accessories.

NEWS CENTER

Focus on the development, production, and sales of micromotor

-

-

[Corporate News] Motor 13 asks

2022-04-15

why does the motor produce shaft current?The current in the axle-bearing-base loop of the motor is called the axial current.

-

-

[Industry News] Staff Skills Contest

2022-04-14

The company holds Staff Skills Contest to strengthen culture construction and improve staffs’ skills regularly.

-

-

[Corporate News] Motor 13 asks

2022-04-15

why does the motor produce shaft current?The current in the axle-bearing-base loop of the motor is called the axial current.